Products & Applications

Product Categories

○ Product Details

The horizontal oxidation furnace equipment can be applied in integrated circuits, discrete devices, POWER, MEMS, and other fields, suitable for oxidation, diffusion, GPP, annealing, alloying, and other processes for 4-8 inch wafer chips.

The oxidation process involves placing the wafer in an oxygen or water vapor environment for high-temperature heat treatment, forming an oxide film on the wafer surface. This film can serve as a barrier layer for ion implantation, an injection penetration layer, surface passivation, or a dielectric layer for device structures.

2. Equipment Parameters and Types:

3. Main Features and Advantages of the Equipment

1★ Powerful operational functionality with a Windows interface and display screen operation, allowing users to conveniently modify process control parameters and monitor various process statuses in real time; equipped with fault self-diagnosis software, significantly reducing maintenance time;

2★ Adopts a reliable industrial computer + PLC mode for fully automated control of furnace temperature, boat movement, gas flow, and valves, achieving complete automation of all process steps;

3★ The program supports manual/automatic operation. After power failure or mid-process shutdown, restarting allows for manual temperature ramping based on the process, saving process time;

4★ Features multiple process pipelines for user convenience;

5★ The cold end uses PT100 to detect ambient temperature for temperature compensation, avoiding the impact of ambient temperature changes on furnace temperature and preventing interlayer interference;

6★ The boat movement control employs high-speed pulse closed-loop control to avoid motor step loss and operational vibration. After completing a cycle, the boat automatically calibrates its position, effectively preventing positioning deviation;

7★ Precise gas flow control with analog signal closed-loop control, strong and weak electrical separation, and standard bus communication for data exchange, enhancing anti-interference capability and ensuring data security; gas valves feature a soft-start function;

8★ Includes multiple alarm functions and safety protection features;

9★ Automatic adjustment of the constant temperature zone, cascade control, and accurate control of the actual process temperature in the reaction tube;

○ Company Profile

Qingdao Yuhao Microelectronics Equipment Co., Ltd. was established in 2008 as a high-tech enterprise integrating R&D, manufacturing, and sales. The company specializes in electric heating furnace equipment, heating furnace thermal fields, and graphite tool processing. Our products and services cater to various industries including electronic components, semiconductor materials, and solar photovoltaic sectors.

?

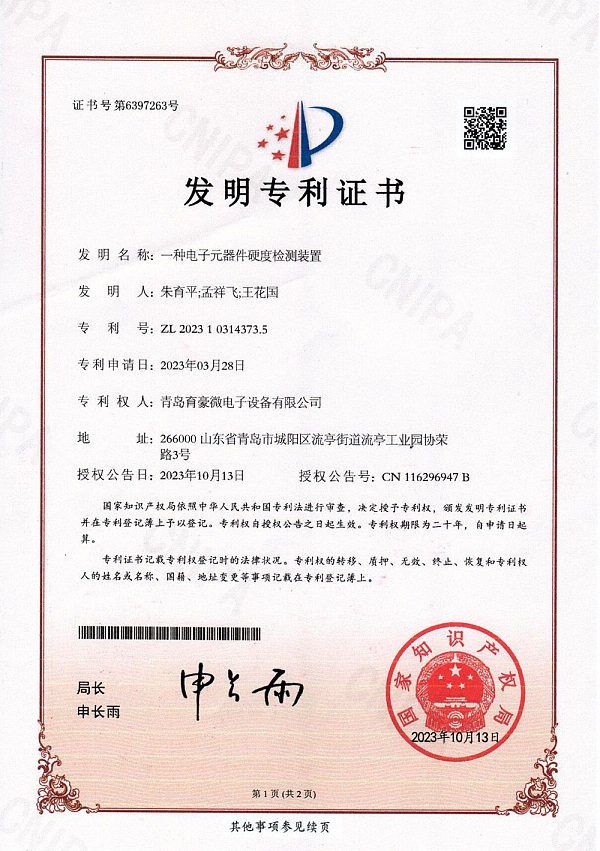

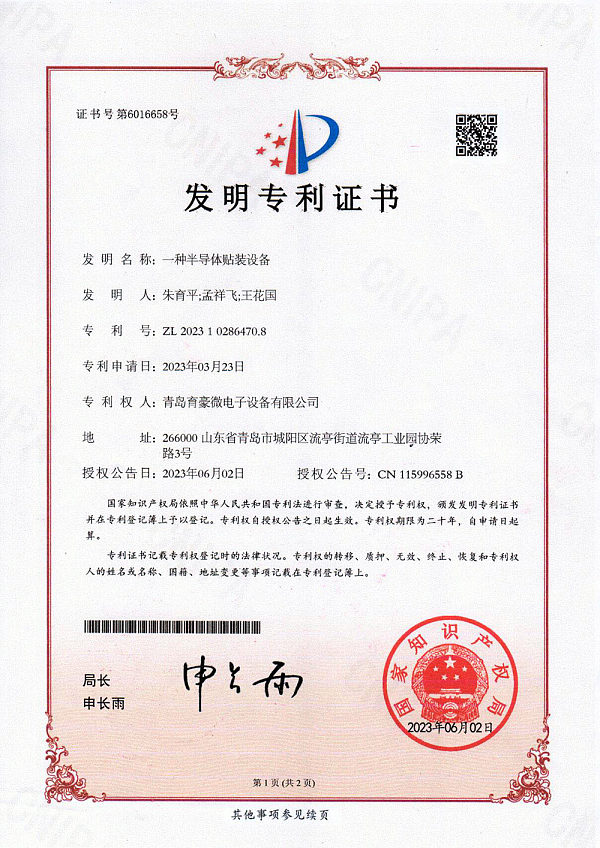

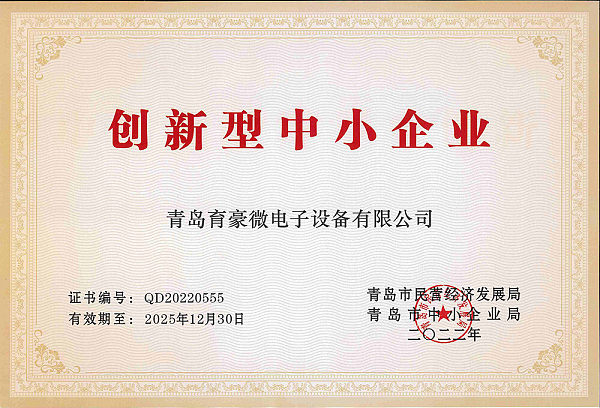

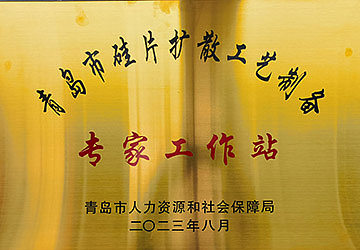

Yuhao is a national high-tech enterprise and a provincial specialized and innovative SME. We hold trademark registration rights and import/export operation licenses, having passed ISO9001 quality management system certification with over 50 patents.

○ Company Certifications

○ Online Consultation

○ Related Recommendations

Message Consultation